| Availability: | |

|---|---|

| Quantity: | |

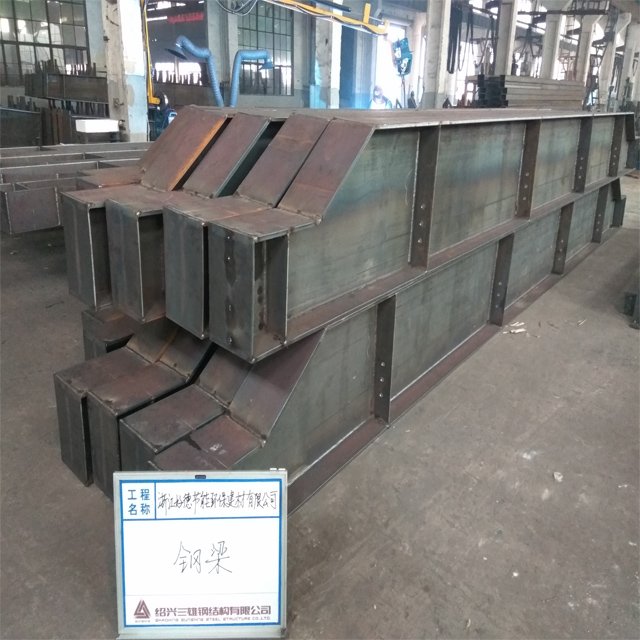

Steel beam for steel structure warehouse

Items | Specification | |

Main Steel Frame | Column | Q235 Welded Steel |

Beam | Q235Welded Steel | |

Cladding system | Roof panel | EPS Sandwich Panel |

Rock Wool Sandwich Panel /Steel Sheet | ||

Wall panel | same with roof panel | |

Accessories | Window | Aluminium Alloy Window |

Rainspout | PVC | |

Steel warehouse building is one kind of steel structure. Steel structure project is the third generation construction. It combines H section and c/z section into the frame with the profiled steel sheet or sandwich panel as the wal and roof. The traditional reinforced concrete construction has aready been taken place by this kind of construction in developed contries. It has many excellent charateristics such as light weight, larger span, less marerial, low cost, less foundation, short building cycle, safe, beautiful, ect. It is widely used in single industrial factory, warehouse, business construction, office, parking lots, residence, multi-layered high building and so on.

STEEL STRUCTURE MEMBERS PRODUCTION (Fabrication) PROCESS :

1. Prepair raw materials : cut steel plate or use internation size H section steel and angle steel,round tube,round steel,square tube etc.;

2. Assembly and welding: our welders will follow the drawings to assembe the steel members and weld them together as a entire beam/column/brace and so on; (Our quality inspector will check the steel pieces after finish welding,this is the first quality check)

3. Sand blast : After finish welding and polishiing,our sand blast effect can reach internation 2.5 high grade,very good for resist rust; (Secondary quality check)

4.Paint : Within 2 hours after sand blast,all the steel members should be paint. Client can choose any color and any brand of paint. (The third quality check)

5. Inspect the goods by client : After we finish a part of fabrication work,we will invite clients to check the goods before we pack the steel frame.

6.Packing and loading : If clients require us to load the goods by close containers,we will pack the steel structure members one by one on the steel skid and tie the whole steel package well. (The fourth quality check )

Features:

1.Item Name: steel structure warehouse/ workshop

2.Steel Material: Q235 and Q345.

3. Connection Type: bolted connection.

4. Preservative Treatment: painted

5. Advantages: fast construction, easy installation, stable structure, earthquake proofing, energy conserving and environment protection.

Technical Advantages:

| A. We have our own technical teams, so we can design, fabricate and install this steel structure workshop according to customers requirement. |

| B. It's very easy to install the steel structure workshop in your there according to our installation drawings. Also, we will supply all technical support during installation and after-sale service. |

| C. One stop shopping---we offer not only steel structure but also sandwich panels and all the accessories. It will ensure the perfect integration between each part. |

| D. fast construction, easy installation, stable structure, earthquake proofing, energy conserving and environment protection. |

Usages.

1. workshop, warehouse, plant.

2. Steel web frame structure.

3. Steel H-column and steel H-beam.

4. Portal frame products.

5. High rise building project.

6. Others steel structure buildings.

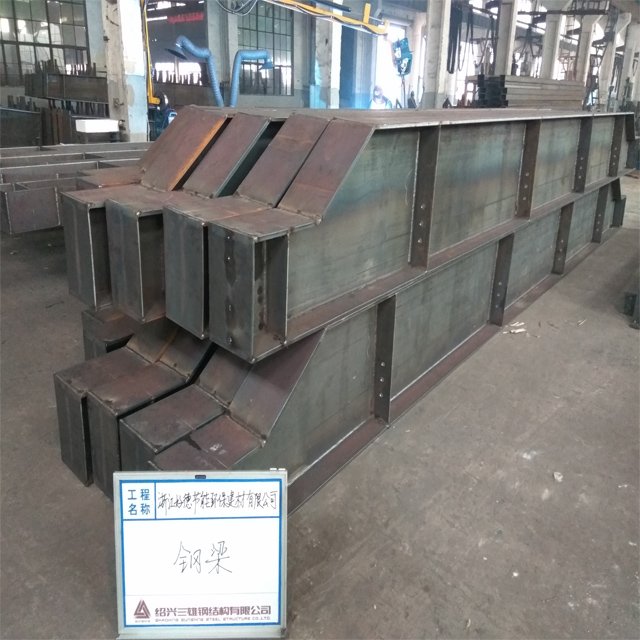

Steel beam for steel structure warehouse

Items | Specification | |

Main Steel Frame | Column | Q235 Welded Steel |

Beam | Q235Welded Steel | |

Cladding system | Roof panel | EPS Sandwich Panel |

Rock Wool Sandwich Panel /Steel Sheet | ||

Wall panel | same with roof panel | |

Accessories | Window | Aluminium Alloy Window |

Rainspout | PVC | |

Steel warehouse building is one kind of steel structure. Steel structure project is the third generation construction. It combines H section and c/z section into the frame with the profiled steel sheet or sandwich panel as the wal and roof. The traditional reinforced concrete construction has aready been taken place by this kind of construction in developed contries. It has many excellent charateristics such as light weight, larger span, less marerial, low cost, less foundation, short building cycle, safe, beautiful, ect. It is widely used in single industrial factory, warehouse, business construction, office, parking lots, residence, multi-layered high building and so on.

STEEL STRUCTURE MEMBERS PRODUCTION (Fabrication) PROCESS :

1. Prepair raw materials : cut steel plate or use internation size H section steel and angle steel,round tube,round steel,square tube etc.;

2. Assembly and welding: our welders will follow the drawings to assembe the steel members and weld them together as a entire beam/column/brace and so on; (Our quality inspector will check the steel pieces after finish welding,this is the first quality check)

3. Sand blast : After finish welding and polishiing,our sand blast effect can reach internation 2.5 high grade,very good for resist rust; (Secondary quality check)

4.Paint : Within 2 hours after sand blast,all the steel members should be paint. Client can choose any color and any brand of paint. (The third quality check)

5. Inspect the goods by client : After we finish a part of fabrication work,we will invite clients to check the goods before we pack the steel frame.

6.Packing and loading : If clients require us to load the goods by close containers,we will pack the steel structure members one by one on the steel skid and tie the whole steel package well. (The fourth quality check )

Features:

1.Item Name: steel structure warehouse/ workshop

2.Steel Material: Q235 and Q345.

3. Connection Type: bolted connection.

4. Preservative Treatment: painted

5. Advantages: fast construction, easy installation, stable structure, earthquake proofing, energy conserving and environment protection.

Technical Advantages:

| A. We have our own technical teams, so we can design, fabricate and install this steel structure workshop according to customers requirement. |

| B. It's very easy to install the steel structure workshop in your there according to our installation drawings. Also, we will supply all technical support during installation and after-sale service. |

| C. One stop shopping---we offer not only steel structure but also sandwich panels and all the accessories. It will ensure the perfect integration between each part. |

| D. fast construction, easy installation, stable structure, earthquake proofing, energy conserving and environment protection. |

Usages.

1. workshop, warehouse, plant.

2. Steel web frame structure.

3. Steel H-column and steel H-beam.

4. Portal frame products.

5. High rise building project.

6. Others steel structure buildings.